China zinc die casting technology – Perfection down to the last detail

We have zinc die casting machines up to 280 t. With modern production methods and management systems, we recognize and record optimal production parameters to ensure the stability of production quality. Precision and functionality are achieved through the use of specially developed means of production and the use of high-quality raw materials.

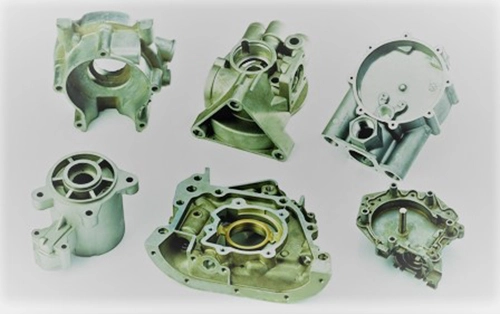

China Zinc Die Casting and Aluminum Die Casting

Furthermore, aluminum die casting molds play a crucial role in the quality of die-cast products. Our own moldmaking department has advanced production technology and efficient team to design and manufacture zinc die casting molds. The coordination of mold making and zinc die casting and aluminum die casting production not only protects the stability of the quality, it also greatly improves production efficiency, thereby