Our company produces plastic injection molds and die-casting molds up to 1.6 meter. Experiencesd engineers work out tailor-made mold solution for customers through modern CAD systems according to the customer’s actual application requirements, strictly control the purchase of raw materials,use systematic and modern processing methods,along with consistant quality management,reduce production costs, improve processing efficiency,achieve to provide customers with the most cost-effective high-quality mold.

In addition to the traditional mold, the company also offers the following special molds for the special needs of the customers:

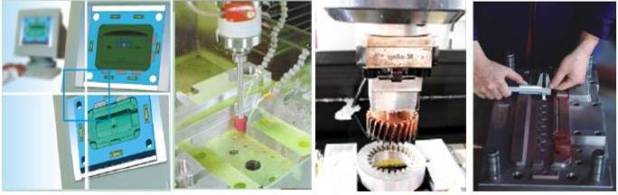

TSF Foaming Mold:For large plastic shell pieces. Structural foam technology achieves high wall thickness, and overcome the internal stress and surface microcosm, reduces injection contraction rate. Compared with traditional injection molding process, it also has advantages of lower cost of the mold.

Multi-Inserts Injecion Mold:Application in electrical and other industries. In the injection molding process heterophasic material components, which should be assembled in the plastic product, are placed in a mold, the molten plastic material and the inserts join and become solidified, so that injection molding and assembly can be achieved in one step, This process reduces production costs.

Plastic Injection Mold made by Aluminium:Application by soft plastics such as PP, ABS, etc.The easy machinability of aluminum reduces tooling cost. The high heat dissipation shortensinjection molding cycle. It is a good solution for small batch products.

Multi-Slides Die-Casting Mold: Applcation by small Zinc-die-casting products, up to 8 slides.Compared with the traditional process, the flexibility to select the parting surface is bigger, secondary processing of products can be reduced. A unique parting surface casting method, does not require vertical flow channel, saves material cost, stabilizes product quality.